ML compact busway is suitable for AC three-phase four-wire and three-phase five-wire systems, frequency 50-60Hz, rated voltage 690V, rated working current 250-5000A in power supply and distribution systems. It is used as an auxiliary equipment for power supply and distribution equipment in industrial & mining enterprises, tall buildings, especially suitable for the renovation of workshops and old enterprises.

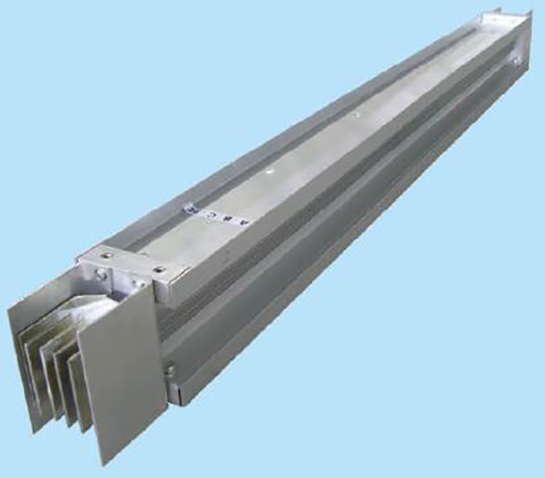

Introduction ML compact busway is suitable for AC three-phase four-wire and three-phase five-wire systems, frequency 50-60Hz, rated voltage 690V, rated working current 250-5000A in power supply and distribution systems. It is used as an auxiliary equipment for power supply and distribution equipment in industrial & mining enterprises, tall buildings, especially suitable for the renovation of workshops and old enterprises. Structural characteristics 1. Heat dissipation ML compact busway adopts an aluminum magnesium alloy outer covering with cooling wings to increase the heat dissipation area. The compact busbar trunking is tightly adhered to each other and the outer covering, so it can withstand large electric and thermal stresses. And it can quickly dissipate the heat generated by the conductive bar, with high carrying capacity. The joint is fastened with insulated bolts and connected with double copper bars, effectively increasing the contact area of the joint, reduces the temperature rise in the joint area. | |

2. New eco-products The compact busway conductive bar is wrapped with flame-retardant cross-linked polyethylene heat shrink tubing, which has casing pipe, with insulation performance and no toxic gas emission when exposed to fire. 3. Flexible wiring The compact busway socket is flexible and convenient to set up, with a large number of sockets that have good universality. When adjusting the position of electrical equipment, there is no need to change the power supply system. |  |

ML compact insulated busway is composed of aluminum magnesium alloy as the protective cover, conductive bar, insulation material, and related accessories. It can be made into an enclosed busway with plug-in junction boxes installed at regular intervals, or into a feeding enclosed busway without a junction box in the middle. In the power supply system of tall buildings, power and lighting lines are often set up separately, and busways are installed vertically along the wall in the electrical shaft as the main power supply line for one or more trips. According to the purpose, a busway generally consists of an initial end busway, a straight-through busway(with or without sockets), an L-shaped vertical [horizontal] bent busway, a Z-shaped vertical (horizontal) ofset busway, a T-shaped vertical (horizontal) three-way busway, an X-shaped vertical (horizontal) four-way busway, a variable capacity busway, an expansion busway, a terminal head, a terminal junction box, a plug-in box, relevant accessories and fastening devices for the busway.

Functional unit

● Straight unit with socket

The plug-in busbar trunking system can be installed vertically or horizontally, with flexible sockets. Both sides can be equipped with sockets, and the minimum spacing between sockets is 575mm. A standard 3-meter busway can be with up to 10 sockets. Users can reserve sockets according to specific situations so that the busbar trunking unit can still adapt to load requirements when the equipment load is changed or increased, it provides users with a safe, reliable, and convenient electricity environment.